Test bench for high-pressure gas valves.

- Home

- Success stories

- Test bench for high-pressure gas valves.

When a product is going to be used in remote countries reliability must be assured. A good and reliable test bench is essential in these cases."

Other success stories

POYAM, AMPO’s valve division, manufactures cryogenic service and high-pressure gas valves. At the end of the manufacturing process, the valves must be checked to ensure that they work properly, ensuring that any leaks (both internal and external) fall within the range permitted by regulations. In order to improve operator safety and the precision of the current test system, it was necessary to build a new test bench, automating the process and using digital sensors. The system must be able to perform the tests with helium at pressure of up to 700 bars, with the option of pressurizing different valve sections automatically.

The product to be tested: http://www.ampo.es/es/products-services/valves.php

Solution provided

Based on client specifications, the following tasks were performeds:

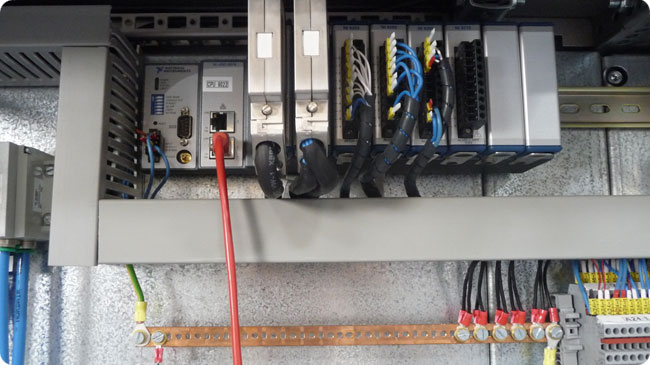

- Cabinet design, including the pressure generating, pressure measurement, temperature measurement and leak flow measurement components. A Compact RIO controller from National Instruments was used.

- Interface cabinet design. Includes an industrial touch screen PC and an Ethernet connection to the main cabinet.

- Supervision during the power cabinet assembly and start-up.

- Creation of the control program in Lobbies.

Advantages

- The 17” touch screen facilitates parameter reading and test configuration. Improved XXX time.

- Configurable test sequence to adapt the bench to tests developed in the future.

- User-friendly interface, thanks to Labview programming. Faster training times for system use.

- Improved system accuracy as the result of the use of digital sensors.

- Makes it possible to test valves remotely, over an Ethernet connection. The operator does not need to be present near components under pressure during the test.